Milwaukee’s Maker of Sought-After Knives

Meet Nate Zimmerman, whose work can be found everywhere from fancy restaurants to D&D tables.

Nate Zimmerman. Photo by Lily Shea.

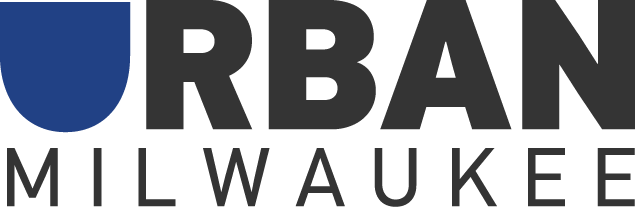

It’s been said that our workspace is a reflection of who we are. If that’s true, Nate Zimmerman is imaginative, multi-faceted and constantly-evolving. There’s a delicate balance of organized chaos — the longer you look, the more there is to discover.

And while it’s not immediately clear to the untrained eye — which may first take in the artwork, action figures, fortune cookies and antlers placed throughout his workshop — Zimmerman is a metalworker. More specifically, he’s the owner and creative force behind ZimKnives, a custom cutlery business.

The contents of his sprawling workshop, 150 E. Albert Pl., is soon to be packed away, as he prepares to relocate his business to 4404 W. North Ave.

The new location includes a storefront where Zimmerman will offer his knife sharpening services, as well as an upstairs apartment, dropping his commute time down to mere seconds.

With several pieces of equipment weighing in at thousands of pounds, the move will be no small feat. Even the smaller equipment will be a big lift. Just one of Zimmerman’s 1925-era anvils — a North German, double-horn model from Sweden, to be exact — weighs in at over 225 pounds.

With the help of a hired trucking company, pallets and a forklift, Zimmerman said he hopes to complete the move by early summer.

Taking a Stab At It

Like many artists, Zimmerman can trace his interest in knifemaking back to childhood. The son of a Milwaukee Art Museum docent and an electrical and computer engineer, he took an early interest in metalwork, which he pursued via jewelry-making classes while attending high school in Waukesha.

In addition to being an engineer, Zimmerman’s dad is an avid woodworker.

“Woodworking stuff was very central to my childhood,” said Zimmerman, noting that his early years spent observing his dad helped shape his future career.

In the midst of earning a theater degree from UW-Milwaukee, Zimmerman responded to a Craigslist advertisement for a knife sharpening job with The Sharp Brothers. Shortly after, he made his first knife.

As he advanced, Zimmerman honed his skills by watching knife making videos on Youtube, and was eventually awarded a scholarship to the New England School of Metalwork for a week-long chefs knife-making class, later returning for several additional courses.

Post-college, Zimmerman started a small workshop out of his parents’ basement, later moving to his current space, where he has operated for the past five years.

In a full circle moment, his dad now stores woodworking materials in the workshop, and has put his engineering skills to work in enhancing several pieces of Zimmerman’s metalworking equipment.

For example, installing an electric controller to modify a heat treating oven that Zimmerman got for free.

“Having an engineer on staff to help out with projects like that is pretty nice,” he said.

Process and Products

At minimum, the process of transforming a sheet of steel into a custom blade takes Zimmerman approximately 10 to 15 hours of work over the course of three days. He typically creates knives in batches of two to four, working each one through the entire process before starting a new batch.

In addition to being high-quality and wickedly sharp, many of Zimmerman’s creations stand out for their design, due to his signature damascus-patterned blades and dyed wood handles.

The damascus finish, recognizable by its swirly appearance resembling wood grain, is created through the fusing of high- and low-carbon steel into a single layer.

The process is both artistic and highly effective, said Zimmerman, who explained that the properties from each alloy combine to give the knife a durable and long-lasting edge.

Just like the blades, ZimKnives’ handles are unique and fully customizable. Zimmerman sources blocks of spalted wood from a friend in Madison, who adds colorful dye and then submerges them in wood hardener. Each block is then carved into multiple handles. Though Zimmerman uses a variety of wood types including ebony and African blackwood, he makes an effort to source midwestern hardwoods for sustainability purposes.

While the bulk of Zimmerman’s work is designed for use in the kitchen, his favorite projects are swords, daggers and other tools inspired by myths, fables and fantasy. For an upcoming commission, Zimmerman is crafting a fantasy dagger for a member of his Dungeons & Dragons group.

Even during monotonous stretches of work, Zimmerman’s brain is occupied by the fantastical. While polishing and grinding blades, he often listens to audiobooks, his latest pick being the Warhammer 40,000 novel series.

The rest of Zimmerman’s workshop is filled with various sharpening tools, which can restore nearly every type of blade — save for ice skates and bandsaws — to peak sharpness.

Zimmerman showcases his work on Instagram and on his website. Commissions, questions and purchases can be directed through either platform.

Come late spring, Zimmerman plans to be up and running at his new storefront, where he will take walk-ins for sharpening while operating his workshop in the back part of the building.

He will also continue to make appearances at Waukesha and Greenfield farmers markets for sharpening services.

Workshop Photos

Finished Knives

New Location

If you think stories like this are important, become a member of Urban Milwaukee and help support real, independent journalism. Plus you get some cool added benefits.