Cream City Ribbon

How to revive a traditional manufactured product, add environmental sustainability, and become a success.

When Eric Crawford, owner of Cream City Ribbon, describes his product it almost sounds like some kind of great dessert. “The ribbon we make is just dyed yarn making it very unique, beautiful, luscious, crunchy and natural,” he says.

Those luscious, crunchy ribbons are made using a very green process in a factory located at 440 W. Vliet, one with quite a history. “We have stories to tell and our products can help tell those stories,” says Crawford.

The building where Cream City Ribbon is located dates back a century, beginning as a leather processing company. This area became part of Milwaukee’s Bronzeville neighborhood that arose in the 1930s. But Bronzeville died after construction of I-43 tore the neighborhood apart and the leather company fizzled into bankruptcy by the mid 1980’s. It was bought and rejuvenated into the ribbon-making business, but the Great Recession hit Cream City Ribbon hard, as many of their Mom-and-Pop clientele went bust, unable to compete with the bigger corporate stores. Enter Crawford, who took over the company about a year ago with the goal of revitalizing the business.

It makes unique unwoven cotton ribbons in an environmentally sustainable way, using soy ink and a water soluble adhesive. “Our goal is for people to use the ribbon for gifts, or companies to use it on products, that then can be recycled into other crafting projects and then can be thrown in the compost bin,” Crawford says. “Think of the amount of garbage produced at Christmas, we want to do our part to reduce that.”

The company employs six workers and rents out two levels in the building. The business office is on the top level and there’s a variety of beautiful ribbon arrangements and projects on several tables throughout the space. A concerted effort has been make the company more environmentally sustainable beyond their ribbons produced.

“I am a green person doing a green job in a green way,” boasts Crawford. “We actively work to carbon offset our packages, our neighbors give us their old packaging material that we then use when shipping packages. We have eliminated printers and have cut down our use of paper by upwards of 50 percent in the last year. For any local shipping we do, I generally try to deliver packages on my bicycle, if the package is small enough.”

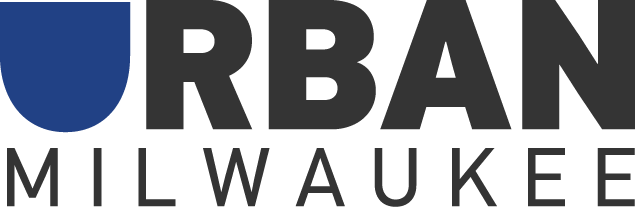

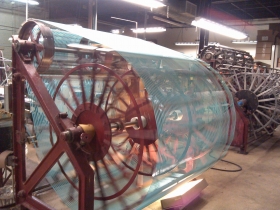

Walking into the lower level of Cream City Ribbon is like taking a step back 100 years; the gorgeous old machinery is organized in the middle of the large open manufacturing area. “The machines are so old, so simple and so beautiful,” says Crawford. “We are using the original process to make ribbon, we are preserving the original artisan process.”

Three people work the machines to produce and process the ribbon onto spools. Each is a master of a craft that can take a decade to learn. The temperature is kept at a strict 85 degrees so the cotton and adhesive can blend together perfectly. The rest of the space is occupied by barrels upon barrels of ribbon that is then spun by hand onto spools. Hundreds of different ribbons are kept on shelves waiting to be shipped throughout the country. The ribbon varies from bold single colors to spotted to a Wisconsin necessity: Packer themed ribbon.

Crawford sees Cream City Ribbon as an example of how to rejuvenate manufacturing as relevant and sustainable businesses. “We should be looking to regenerate and sustain these legacy businesses. You know, when we think about the great life that Uncle Bob had 50 years ago, a good salary, able to take vacations to Florida when he wanted, that’s what our young people should be striving for, good sustainable jobs that came from manufacturing.”

A model of sustainability and good marketing has helped Cream City Ribbon thrive in an economic climate that has not been friendly to old-style manufacturing. “We have to be thinking about moving the infrastructure of manufacturing to the Web. Make your product relevant again. It’s all about good old customer service and marketing the right product.”

Photo Gallery

City Business

-

New Bookstore Tailored For Children of Color

Apr 14th, 2022 by Michael Holloway

Apr 14th, 2022 by Michael Holloway

-

Vintage Clothing Shop For Brady Street

Feb 26th, 2021 by Graham Kilmer

Feb 26th, 2021 by Graham Kilmer

-

All About Lion’s Tooth Bookstore

Jan 19th, 2021 by Michael Holloway

Jan 19th, 2021 by Michael Holloway

So great to hear about local businesses!

Next time maybe add a link to their site? http://www.creamcityribbon.com

@Sarah Good point… I added a link.

If you wish to purchase our ribbon online, please enter the code “UrbanMilwaukee” to receive 35% of your entire order. Note free shipping on orders over $100 (after discount).

We hope this is an appropriate offer for the readers.

Cream City Ribbon Team