Marquette biochemist identifies blueprint for enzyme that makes ammonia

Discovery could lead to energy savings in fertilizer production

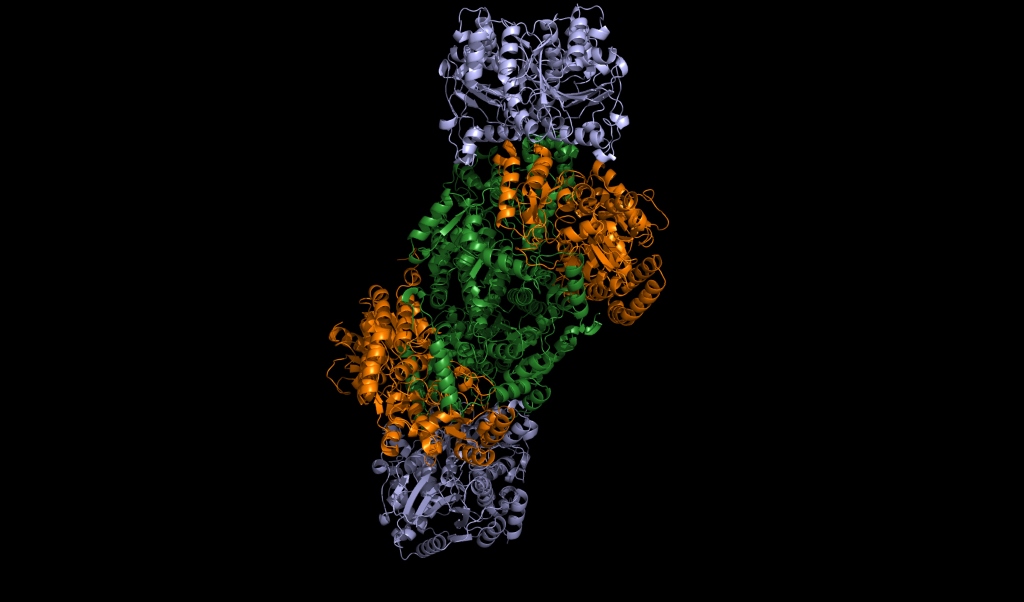

Marquette biochemist identifies blueprint for enzyme that makes ammonia. Image courtesy of Marquette University.

MILWAUKEE — A Marquette University biochemist led a team of researchers in discovering that the enzyme that creates ammonia uses a complex two-cylinder engine like mechanism for function — a process that is markedly more efficient than the man-made one used in industrial ammonia production.

The research, which was funded by the National Institutes of Health and the Department of Energy, has implications to the commercial fertilizer industry, which artificially produces ammonia, the preferred nutrient for plant growth on Earth. That process supports the food needs for more than 40 percent of the human population.

According to Dr. Edwin Antony, assistant professor of biological sciences at Marquette, the industrial nitrogen breakdown— called the Haber-Bosh process — uses a vast amount of energy, usually from fossil fuels. If scientists can engineer the ammonia-producing enzyme from bacteria called nitrogenase for industrial-scale ammonia production, it would be a tremendous achievement in agriculture and food production, he said.

The Marquette biochemist and his collaborators found that the long-held presumption that the two symmetrical halves worked independently to make ammonia was incorrect. Instead, the two sides cooperate, alternating through different steps to make efficient use of the complex enzyme. The team reported their findings in a paper published this month in the Proceedings of the National Academy of Sciences.

“Our findings provide the blueprint for how nitrogenase functions and is a critical piece of information to make this a reality,” Antony said.

“This is in analogy to a car engine having two cylinders where one cylinder fires first followed by the next,” Antony said. “The sequential action of the two cylinders made the entire engine work in a step-wise manner.”

The enzyme is found in bacteria called diazotrophs, which reside in the root nodules of plants, where they breakdown dinitrogen and generate ammonia that plants use for growth.

The researchers found that when one side moves one electron through the nitrogenase machine, the complex shifted in shape, obscuring the other side. Since the sides are symmetrical, moving one side up forces the other side to move down, positioning different parts of the machine for different chemical reactions.

Other researchers were from Utah State University, Northwestern University, Virginia Tech University and the Pacific Northwestern National Laboratory.

NOTE: This press release was submitted to Urban Milwaukee and was not written by an Urban Milwaukee writer. While it is believed to be reliable, Urban Milwaukee does not guarantee its accuracy or completeness.

Mentioned in This Press Release

Recent Press Releases by Marquette University

New Marquette Law School Poll finds large majority of Wisconsin voters not yet tuned in to who is running in major 2026 elections

Oct 29th, 2025 by Marquette UniversityNo candidate has established strong position in public favorability in governor, state Supreme Court races; large majorities of voters undecided

New Marquette Law School National Survey Finds Large Majority Think Political Violence is a Big Problem, But With Sharp Partisan Differences

Oct 1st, 2025 by Marquette UniversityAmericans are overall pessimistic on reducing intense political conflict; half of those polled say heated language by leaders makes violence more likely