Wisconsin Has Developed Technique That Could Recycle Flexible Plastics

Process developed by UW-Madison professor and Green Bay company still in early stages.

Convergen Energy in Green Bay could host a commercial demonstration facility for a new type of plastic recycling that could cut down on landfill waste. Photo courtesy of Convergen Energy

A University of Wisconsin-Madison professor and a Green Bay company are working together to upscale a new recycling technique that could help keep flexible plastics out of landfills.

The project is still in the early stages — with hopes to open a commercial demonstration facility in Green Bay by 2025 at the earliest.

Wisconsin has a robust packaging industry that employs 43,000 people — 25,000 of which are in flexible packaging — Huber said.

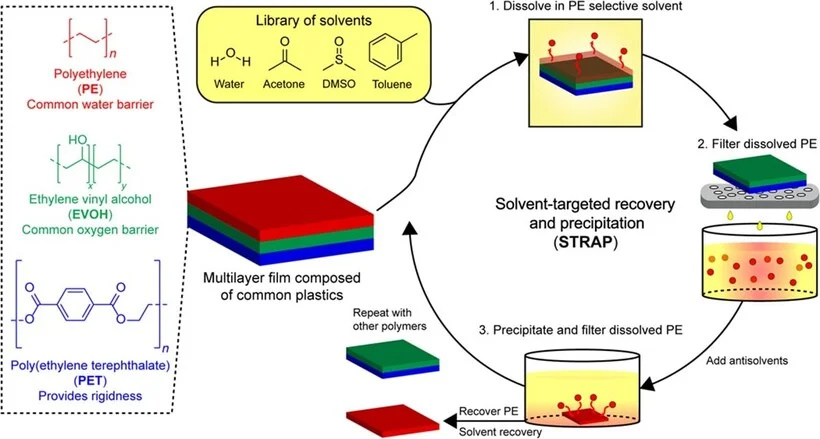

That’s why researchers developed a plastic recycling process called “solvent-targeted recovery and precipitation,” or STRAP, he said. That research was supported by a grant from the U.S. Department of Energy.

“What we do with STRAP is pick a solvent that will selectively dissolve one plastic. We then keep that hot while it’s dissolved, we separate the solvent from the undissolved plastic and then we cool it down,” Huber said. “The plastic precipitates and then you get the pure plastic back that you can use to reuse your original material or remake your original material.”

This graphic helps illustrate key steps in the solvent-targeted recovery and precipitation, or STRAP, process for segregating these component resins into pure, recyclable streams using a series of solvent washes. Photo courtesy of the University of Wisconsin-Madison

He said efforts to market STRAP have been aided by a partnership with Amcor, a global packaging company based in the Fox Cities. Amcor liked the STRAP technology and asked for samples of the material produced by the process that exceeded what researchers could produce in a lab, Huber said.

Convergen Energy CEO Ted Hansen said the company already receives materials necessary for STRAP, which it converts into fuel pellets that companies and utilities use to produce steam and electricity.

He said there are four main steps for commercializing, or upscaling, STRAP. First is the lab phase where researchers are working with small quantities of material. Second is a pilot phase where they’re working in a larger-scale lab that’s smaller than a commercial facility. Third is a commercial demonstration unit that’s able to produce large quantities of product at a profitable scale. And fourth is a true commercial facility that’s profitable.

Right now, Hansen said efforts to commercialize STRAP in Wisconsin are still in the lab phase, and Convergen Energy is in discussions to craft a commercial demonstration facility.

“What we can do is put in a commercial demonstration unit, strip out some of these non-recyclable plastics that we’re currently bringing into the facility and you can run them through the STRAP process and now have a recycled polymer that we could sell back to the producers of flexible films and other types of plastics,” he said.

These are fuel pellets produced by Convergen Energy using nonrecyclable material. The pellets can be used by utilities to produce steam or electricity. Some of those materials could also be used in the STRAP process. Photo Courtesy of Convergen Energy

Hansen said the earliest Convergen Energy’s facility would open is 2025, but it could be 2027. The facility would produce 4,000 to 5,000 tons of recycled material per year, and a full-scale commercial operation would double that, he said.

While a commercial demonstration facility may still be several years out, Huber said STRAP’s potential is limitless, especially as Americans are living in the “plastics age” with almost all food products packaged in plastics. Much of that plastic ends up in landfills or is burned, which can have harmful environmental impacts.

“It’s a super important industry for the state of Wisconsin, but we don’t really have technology to recycle most of these plastics that are being produced,” he said. “Wisconsin should also try to become the leader with plastic recycling and how we can more sustainably use the plastic material — I think it’s a critical thing for the plastic industry.”

Listen to the WPR report here.

New recycling technique developed in Wisconsin could help keep flexible plastics out of landfills was originally published by Wisconsin Public Radio.

I love reading about scientists trying to invent ways to deal with pollution problems and improve our Earth. Another reason to increase funding to the University and encourage research.

Bravo!

Science works!