Ship-Loading Equipment Makes 1,500-Mile Trip To Port Milwaukee

Part of largest investment in port in 60 years.

An essential piece of the largest Milwaukee port investment in 60 years floated into town in recent weeks.

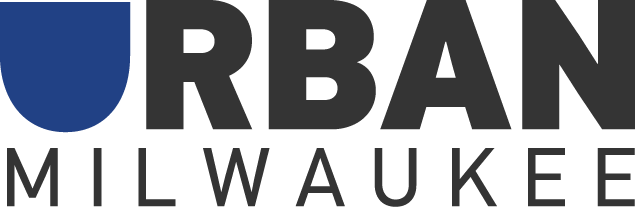

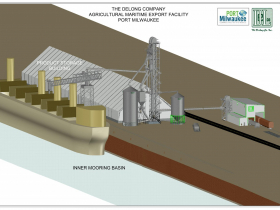

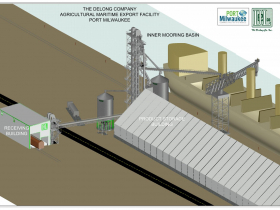

The “ship loader,” which will be used at DeLong Company‘s new agricultural maritime export facility, was delivered and is now being installed along Milwaukee’s inner harbor. When complete, the large, overhead system will be used to load up to 40,000 bushels (1,100 metric tons) per hour onto either barges or ships.

The structure it will be attached to, the Agricultural Maritime Export Facility (AMEF), is a first-of-its-kind facility for the Great Lakes. The $40 million complex is being developed as a public-private partnership between the city and Delong, with financial support from the state and federal governments. It will be used to ship an ethanol byproduct to other corners of the world for use as animal feed.

Construction started on the project last fall and became very visible in the summer when Michels Corp. topped off the metal tower that will be used in the conveyance system. A large storage building is now taking shape to its north.

“We at DeLong are excited to see the progression of this project. Our ship loader is currently being installed and we hope to have final project completion by March 2023,” said DeLong vice president of grain Bo DeLong in a statement.

“Delivery and installation of the ship loader, as part of the future agricultural maritime export facility, is a turning point in our efforts to realize new agricultural opportunities and advance economic activity in the city and throughout the Great Lakes region,” said Port Milwaukee Director Adam Tindall-Schlicht in a statement. “The Port is looking forward to next year when the terminal comes to life. Wisconsin-produced cargoes handled on Jones Island will be multiplied through new rail and vessel efficiency at the DeLong terminal.”

A rail yard, capable of storing 110 hopper cars, and a truck terminal, will feed into storage facilities that can store 45,000 metric tons (1.7 million bushels) of the byproduct. Located directly adjacent to the inner harbor, the facility will then be capable of loading 6,000 metric tons of the byproduct per day into vessels that can carry 10,000 to 20,000 metric tons. Project partners hope to export between 160,000 to 300,000 metric tons annually, with an estimated $40 million worth of goods being shipped in the first year.

DeLong already coordinates exports of what is called dry distillers grain with solubles (DDGS), via shipping containers and coastal ports, to Asia. But the new facility will provide a purpose-built facility and logistics network to compete in many more markets. It will also allow DeLong to avoid using shipping containers that are ill-suited for the moisture-laden product and in increasingly short supply. Corn and soybeans are also expected to be exported through the facility, according to a February 2021 report.

Officials will want to see that impact come to fruition. The cost of the project has risen by nearly 33% since it was first announced two years ago. The federal government is contributing $15.89 million via a grant and the city (via borrowing) is contributing $5.7 million. Wisconsin has increased its $6.15 million, awarding a new $1.5 million loan. DeLong is covering the remaining cost through a mix of financing sources.

DeLong is leasing a 4.42-acre site, 1711 S. Carferry Dr., from the city-owned port and will own the facility built atop it. The company will pay approximately $3.5 million in lease payments over 30 years. If DeLong doesn’t renew its lease, the port will have an option to buy the facility.

The new complex will accept deliveries on the east side of S. Carferry Dr. and transfer materials overhead to storage facilities on the harbor side of the street. Those storage buildings include a 19-inlet flat storage building and multiple upright storage silos made of galvanized steel. Disused buildings on the site were demolished earlier this year.

According to a DeLong representative, DeLong hired Michels Corp. to perform site work on the property, The Scharine Group to construct the conveyance systems and Legacy Building Solutions to build the flat storage building.

A press release from Port Milwaukee announcing the equipment delivery does not give the manufacturer’s name, but a description of a trip starting in New Orleans indicates it was likely made by Agrico Sales.

Photos

Renderings

If you think stories like this are important, become a member of Urban Milwaukee and help support real, independent journalism. Plus you get some cool added benefits.

Eyes on Milwaukee

-

Church, Cupid Partner On Affordable Housing

Dec 4th, 2023 by Jeramey Jannene

Dec 4th, 2023 by Jeramey Jannene

-

Downtown Building Sells For Nearly Twice Its Assessed Value

Nov 12th, 2023 by Jeramey Jannene

Nov 12th, 2023 by Jeramey Jannene

-

Immigration Office Moving To 310W Building

Oct 25th, 2023 by Jeramey Jannene

Oct 25th, 2023 by Jeramey Jannene